WHERE CAN I USE PROTECTICOAT ?

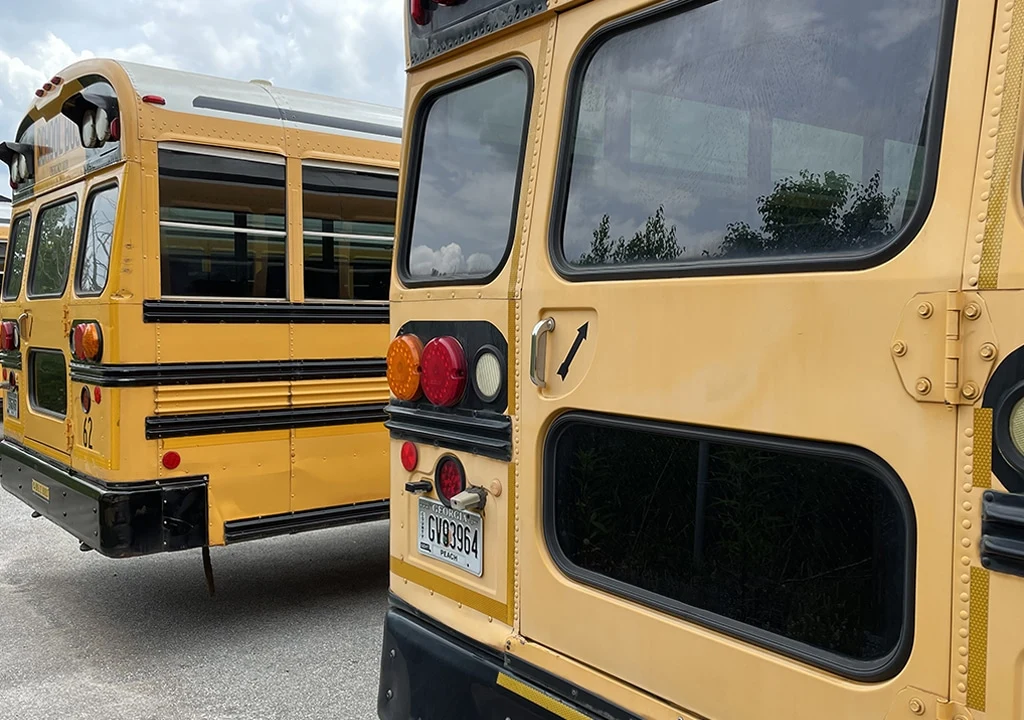

Protecticoat is made with a naturally-occurring, biodegradable solvent and maximum amount of UV inhibitor to restore, seal, and protect many surfaces including single stage paint, plastics, and fiberglass. Single stage paint is paint that does not have a clear coat applied over it. Protecticoat can be used to restore tractors, school buses, patio furniture, and many other items around the house and farm.

Where not to use Protecticoat

Do not use on clear coat, automobiles, plexiglass, or FRP (fiberglass reinforced plastic).

Protecticoat products only ship to the lower 48 states. (excludes Alaska, Hawaii, Canada, Puerto Rico and Europe)

WHY PROTECTICOAT ?

Protecticoat is a revolutionary product that has been designed to make your outdoor items look as good as new and protect them from sunlight exposure, salt spray, and other atmospheric contaminants. Once applied, Protecticoat will not yellow, crack, or peel. Protecticoat restores deep colors in oxidized surfaces - like RVs, tractors, school buses, metal fencing, patio furniture, and more. With its unique blend of polymer resin, it penetrates deeply into the pores and bonds for maximum color retention. Its restorative protection is key to preventing future problems. Easy application allows you to skip the massive amount of time and energy that is required during the buffing process while providing a longer lasting finish.